Premier Ceramic Spray Coating: Unmatched Defense and Luster

Premier Ceramic Spray Coating: Unmatched Defense and Luster

Blog Article

Getting Expert Results With Ceramic Spray Finishing: Proven Approaches and Finest Practices Revealed

As specialists in the area of automotive detailing and surface security are regularly seeking means to elevate the quality of their work, the application of ceramic spray layers has emerged as a game-changer. The attraction of achieving a perfect, long-lasting completed with minimal initiative is obvious. However, the path to understanding this method is paved with subtleties and details that require attention. Understanding the crucial tools, surface prep work techniques, specific application approaches, and upkeep strategies are key elements in the mission for professional-grade outcomes. By revealing the tested techniques and ideal methods behind ceramic spray layer, a world of possibilities opens for those looking to elevate their craft and provide flawless coatings.

Advantages of Ceramic Spray Finish

The advantages of making use of ceramic spray coating in different applications are well-documented and widely recognized in the automobile and commercial markets. Ceramic spray finishings provide exceptional security versus ecological pollutants, UV rays, chemicals, and oxidation, offering a durable guard for surfaces.

In addition, ceramic spray coatings produce a hydrophobic surface that pushes back water and protects against water places, making cleaning and maintenance easier and less time-consuming. In conclusion, the benefits of ceramic spray layer make it a preferred selection for shielding and enhancing surface areas in a range of applications.

Vital Devices and Materials

Having recognized the advantages of ceramic spray finishing, it is crucial to lay out the crucial devices and products required for its effective application in various markets. To accomplish expert results, the adhering to devices and materials are vital:

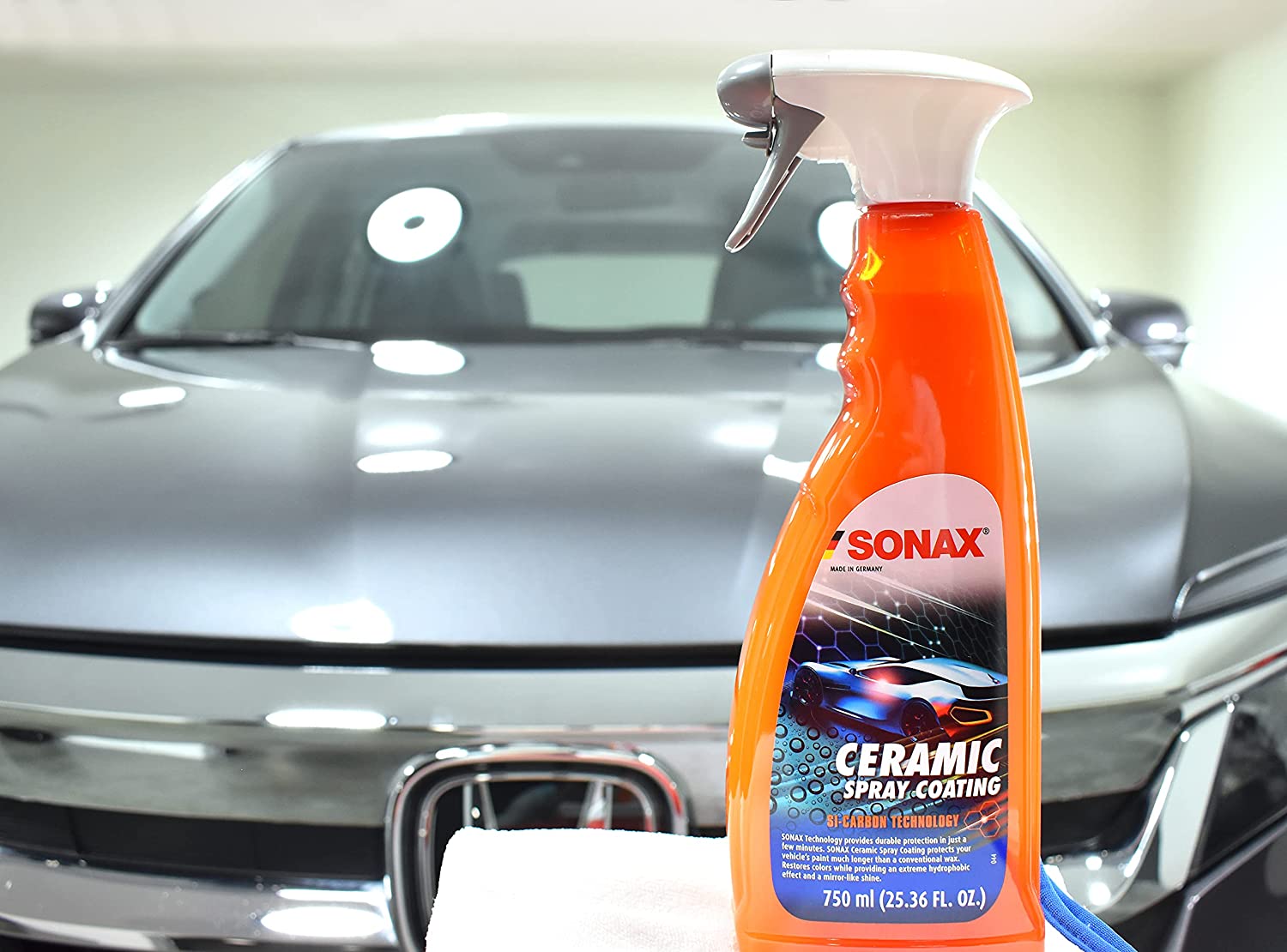

Ceramic Spray Finishing: The heart of the process, the ceramic spray covering itself supplies the protective layer that boosts resilience and visual appeals. - ceramic spray coating

Microfiber Towels: Used for cleaning down the surface area before using the ceramic spray finish and for buffing off excess item after application.

Spray Bottles: Necessary for uniformly dispersing the ceramic finish onto the surface area.

Protective Equipment: Masks and gloves to ensure safety and security during the application procedure.

Polishing Compound: For preparing the surface by eliminating any kind of blemishes before using the ceramic finishing.

Clay Bar: Aids in decontaminating the surface area by eliminating ingrained bits, guaranteeing a smooth application.

Application Pads or Applicators: Made use of for uniformly spreading out the ceramic spray finish onto the surface.

Appropriate Surface Area Preparation Strategies

Effective surface area prep work is basic to making sure the successful application of ceramic spray layer in different sectors. To attain optimal outcomes with ceramic spray layer, appropriate surface preparation strategies must be employed.

The very first step in surface area preparation is complete cleansing. ceramic spray coating. Any dust, residue, wax, or grease have to be completely removed from the surface to guarantee appropriate bond of the ceramic layer. This can be done utilizing a devoted surface area or a mild detergent cleaner

Following, the surface area needs to be brightened to eliminate any type of blemishes such as swirl marks or scratches. This step not just boosts the look of the surface area but also makes certain a smooth and also application of the ceramic coating.

Application Tips for Optimal Outcomes

To make certain outstanding end results with ceramic spray layer, precise interest to application methods is critical complying with the careful surface preparation treatments. When using ceramic spray finish, it is crucial to operate in a controlled atmosphere without straight sunshine or solid winds. Optimum application conditions normally consist of moderate temperatures and low humidity degrees to assist in proper treating and bonding of the layer to the surface area.

Previous to application, shake the ceramic spray finish bottle vigorously to guarantee the formula is well blended. It is vital to work in little sections to guarantee thorough application and stop the finishing from drying too soon.

After applying the ceramic spray layer, enable enough time for it to heal according to the maker's directions. As soon as treated, use a quality microfiber towel to gently rub the surface to a high gloss surface. By following these application tips diligently, you can attain ideal results and make the most of the safety benefits of ceramic spray layer.

Upkeep and Longevity Methods

Sustaining the longevity and protective qualities of ceramic spray finishing needs consistent and methodical upkeep techniques. To make sure the finish continues to be effective, routine cleaning with a pH-neutral vehicle shampoo is vital.

Periodic inspection of the coating is additionally critical for recognizing any type of locations that might need touch-ups or reapplication. This can be done by performing a simple water beading examination or visually inspecting the surface area for any type of indicators of wear. Resolving any issues without delay can aid maintain the finish's protective buildings and prolong its life-span.

Moreover, staying clear of severe chemicals, abrasive cleansers, and automated automobile washes can assist protect the integrity of the ceramic spray covering. By following these upkeep approaches, professionals can ensure their ceramic-coated cars keep a high level this article of defense and aesthetic charm for an extensive period.

Final Thought

In conclusion, attaining professional outcomes with ceramic spray coating requires mindful consideration of vital devices and materials, visit the website appropriate surface area preparation strategies, and application tips for optimal results. By complying with tested approaches and finest practices, maintenance and durability of the coating can be made the most of. It is essential to comply with these standards in order to attain the preferred specialist results and guarantee the efficiency of the ceramic spray coating.

As professionals in the field of auto detailing and surface area protection are constantly seeking methods to elevate the high quality of their job, the application of ceramic spray finishings has actually emerged as a game-changer.Furthermore, ceramic spray finishes develop a hydrophobic surface that wards off water and prevents water places, making cleaning and upkeep much easier and much less time-consuming. In verdict, the benefits of ceramic spray finish make it a recommended selection for protecting and enhancing surface areas in a range of applications.

To make sure extraordinary outcomes with ceramic spray finishing, careful attention to application strategies is extremely important complying with the precise surface area preparation treatments.In final thought, accomplishing professional results with ceramic spray finish calls for mindful factor to consider of necessary devices and products, proper surface preparation techniques, and application suggestions for optimal outcomes.

Report this page